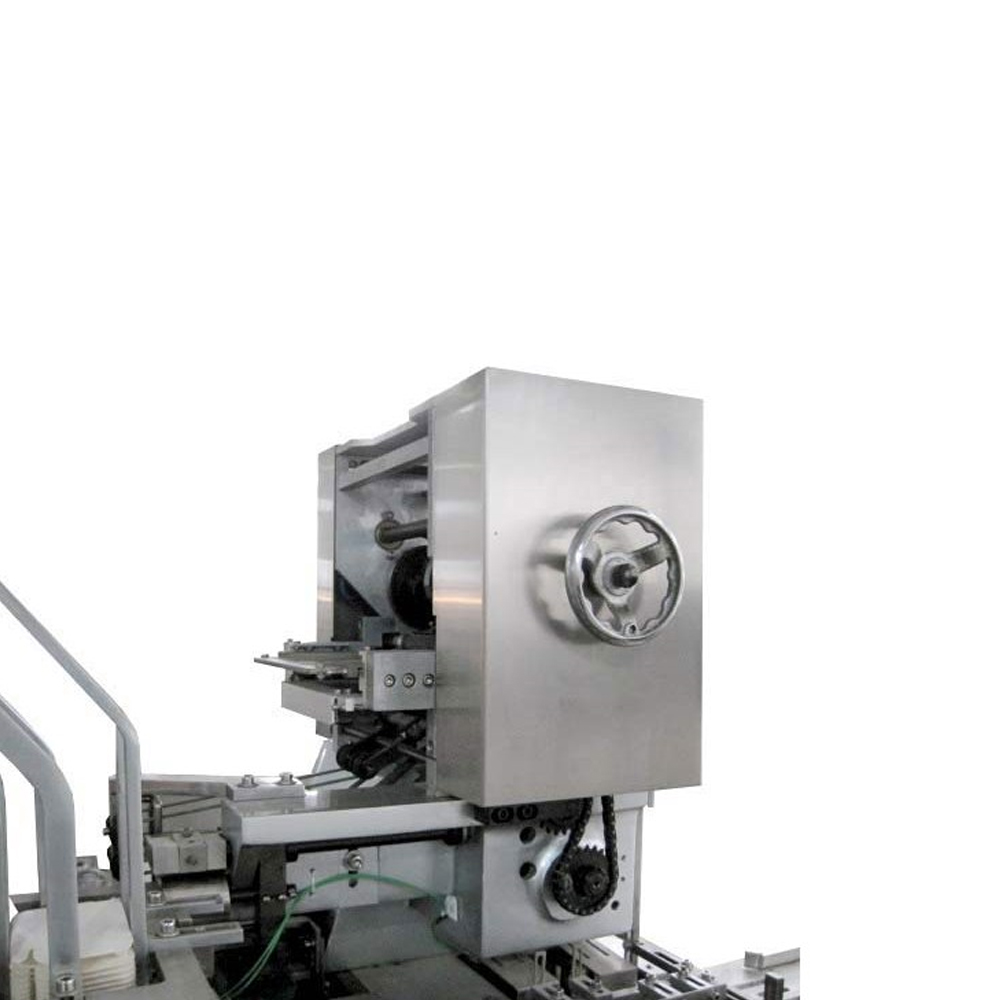

Carton Packing Machine

Eximph Technology Co. Limtied offers continuous-cycle carton packing machines. This equipment is designed for packaging blisters, vials, ointments, and toothpaste into cardboard boxes and is used in the pharmaceutical, cosmetic, and dietary supplement industries. The machine easily integrates into a line with blister machines and group packaging machines, with various placement options (inline, corner, etc.).

GMP Certified

Quality Assured

ISO Compliant

International Standards

High Performance

Proven Results

Key Advantages

Touch Screen control system for easy operation and visual monitoring of alerts.

Servo drives for precise control of movement parameters.

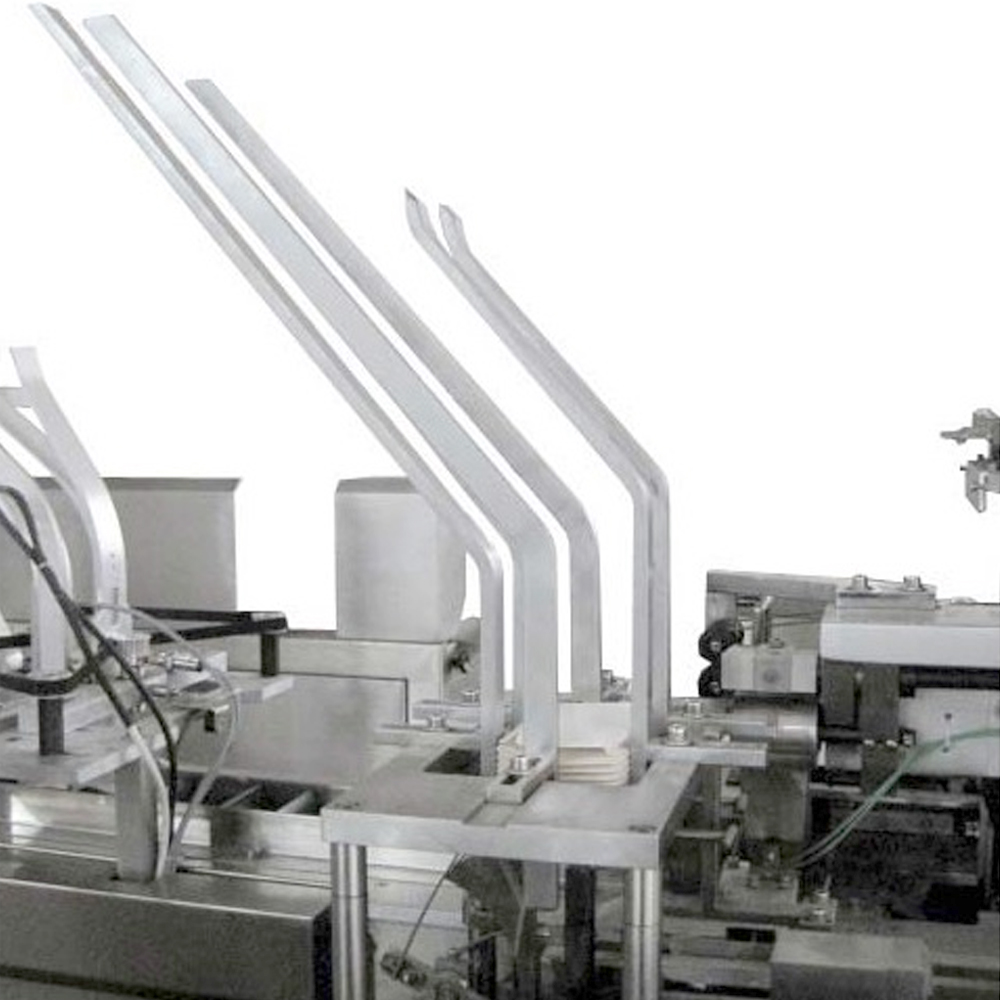

Adjustable magazine sizes for quick reconfiguration to different packaging materials.

Protective guard lifts for convenient access to the machine's working area.

Quick reconfiguration and format change capabilities.

Design ensures unobstructed access to all machine parts for easy setup, cleaning, and maintenance.

Fully compliant with GMP standards.

Ready to Get Started?

Contact our pharmaceutical equipment specialists for detailed specifications, pricing, and custom configuration options.

Technical Specifications

| Model | CBM-100 |

| Performance (packs/min) | 100 |

| Maximum Pack Size (mm) | 120 x 70 x 30 |

| Minimum Pack Size (mm) | 70 x 30 x 10 |

| Maximum Instruction Size (mm) | 260 x 190 |

| Minimum Instruction Size (mm) | 100 x 100 |

| Installed Power (kW) | 2.2 |

| Dimensions (mm) | 950 x 1050 x 1500 |

| Weight (kg) | 750 |

Related Equipment

Wet granulation mixer

Eximph Technology Co. Limited offers wet granulation mixers designed for mixing substances and powdery materials, followed by granulation to produce pharmaceutical preparations. This equipment is relevant for the pharmaceutical, chemical, food, ceramic industries, and production involving metal-containing powders.

Dry Granulation Dryer

Eximph Technology Co. Limtied offers fluid bed dryers in FB, FBG, and FBGP series under the QUARCO brand. This equipment is designed for granulating substances, drying the resulting granules, and mixing substances in a fluidized bed. The dryers differ in their functionality: FB series for drying granules, FBG series for drying and granulation, FBGP series for drying and granulating, coating granules, and pellet production. These dryers are widely used in the pharmaceutical and food industries, as well as in the production of dietary supplements and compound feeds.

Dust Remover

The C&C200G series dust removers represent the latest model with an advanced design. Equipped with dual functionality for dust removal and upward tablet transfer. The inlet of the dust remover can be adjusted to match the height of any model of tablet press, and the outlet is aligned with a metal detector. This setup allows for the assembly of a production line that ensures dust removal, tablet lifting, and metal detection.