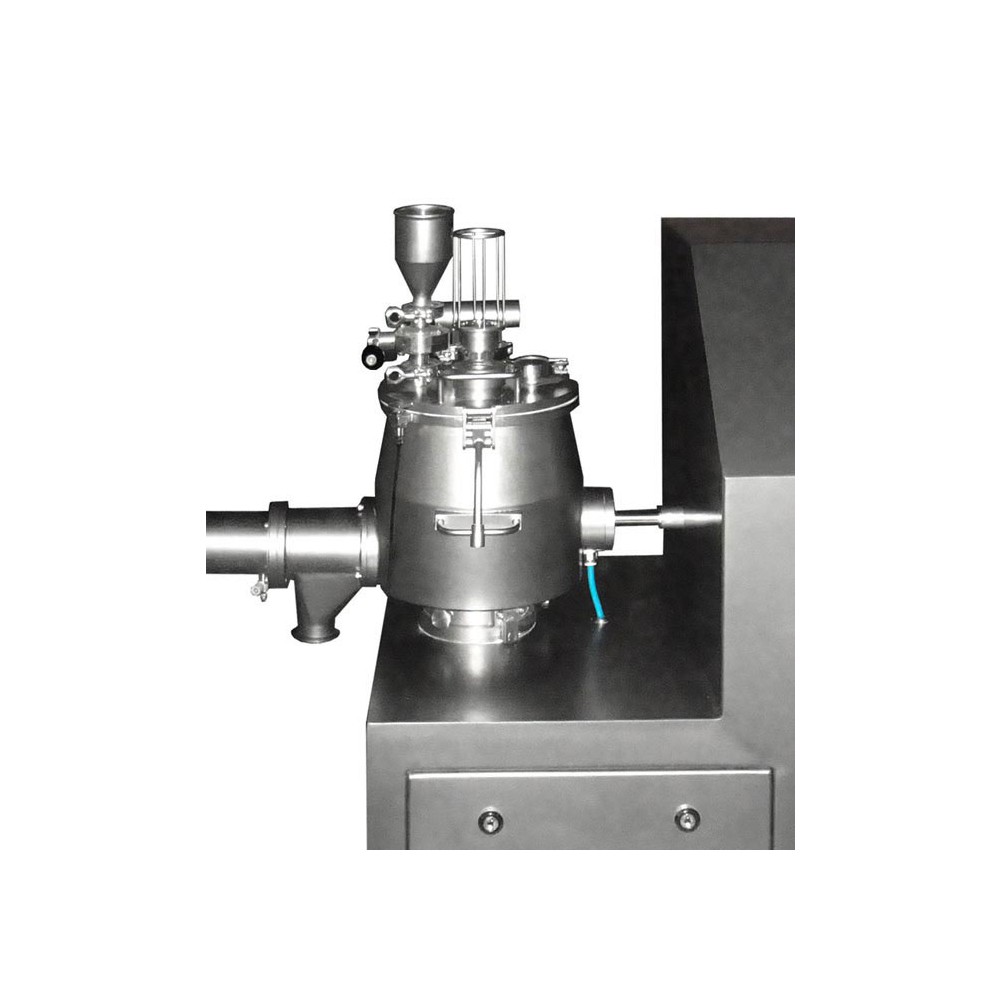

Wet granulation mixer

Eximph Technology Co. Limited offers wet granulation mixers designed for mixing substances and powdery materials, followed by granulation to produce pharmaceutical preparations. This equipment is relevant for the pharmaceutical, chemical, food, ceramic industries, and production involving metal-containing powders.

GMP Certified

Quality Assured

ISO Compliant

International Standards

High Performance

Proven Results

Key Advantages

Conical material tank

Automatic lid lifting system using pneumatic cylinder

Jacketed main tank for heating or cooling during processing (Optional)

Frequency control of mixer drive motors for optimal speed selection of the mixer and chopper depending on product complexity

Air filter to prevent dust contamination in the room

Central control system with a touchscreen and programmable logic controller for easy and intuitive process management

Compact design reduces energy consumption by up to 20% and saves valuable space

High polishing quality (0.5 µm) of the internal surface

Safety features: locks on the main and discharge hatches and automatic power cut-off when any hatch is opened

Contact surfaces made of high-quality alloy steel AISI304

Fully complies with GMP standards

Ready to Get Started?

Contact our pharmaceutical equipment specialists for detailed specifications, pricing, and custom configuration options.

Technical Specifications

| Full Tank Volume | 20L | 50L | 100L | 150L | 250L | 400L |

| Working Volume | 14L | 35L | 70L | 105L | 180L | 280L |

| Product Load | 3-5kg | 10-22kg | 25-35kg | 45-60kg | 75-110kg | 120-200kg |

| Mixer Speed | 25-500 rpm | 25-500 rpm | 6-200 rpm | 6-200 rpm | 6-200 rpm | 5-160 rpm |

| Mixer Drive Power | 2.2 kW | 5.5 kW | 7.5 kW | 11.5 kW | 15 kW | 22 kW |

| Chopper Speed | 100-3000 rpm | 300-3000 rpm | 300-3000 rpm | 300-3000 rpm | 300-3000 rpm | 300-1500 rpm |

| Chopper Drive Power | 0.75 kW | 1.5 kW | 2.2 kW | 3.7 kW | 5.5 kW | 7.5 kW |

| Dimensions (L×W×H) | 1560 x 540 x 1430 mm | 1900 x 700 x 1600 mm | 1900 x 750 x 1600 mm | 2100 x 850 x 1700 mm | 2300 x 950 x 2275 mm | 2700 x 1200 x 2750 mm |

| Weight | 350 kg | 500 kg | 1050 kg | 1200 kg | 1350 kg | 2360 kg |

Related Equipment

Dry Granulation Dryer

Eximph Technology Co. Limtied offers fluid bed dryers in FB, FBG, and FBGP series under the QUARCO brand. This equipment is designed for granulating substances, drying the resulting granules, and mixing substances in a fluidized bed. The dryers differ in their functionality: FB series for drying granules, FBG series for drying and granulation, FBGP series for drying and granulating, coating granules, and pellet production. These dryers are widely used in the pharmaceutical and food industries, as well as in the production of dietary supplements and compound feeds.

Dust Remover

The C&C200G series dust removers represent the latest model with an advanced design. Equipped with dual functionality for dust removal and upward tablet transfer. The inlet of the dust remover can be adjusted to match the height of any model of tablet press, and the outlet is aligned with a metal detector. This setup allows for the assembly of a production line that ensures dust removal, tablet lifting, and metal detection.

Capsule Polisher

Capsule polishers of the C&C100C series combine dual functionality for polishing and lifting capsules. The inlet of the polisher can be connected to any model of capsule filler, and the outlet can be connected to a capsule sorter and metal detector. This setup allows for the creation of a production line that ensures polishing, lifting, sorting, and metal detection of capsules. The model is developed using advanced technologies and achievements in robotics.